ONZE SCHUIFAFSLUITERS

LEVERERANCIER VAN SCHUIFAFSLUITERS

Wedge Gate Valve (Bolted Bonnet type)

Pressure Seal Gate Valve

Through Conduit Double Expanding Gate valve

Through Conduit Slab Gate valve

Forged Steel Gate Valve

BELANGRIJKE INFORMATIE

Al onze beschrijvingen en benamingen van specifieke kleppen en afsluiters zijn in het Engels

| A)Operation Large handwheels for easy operation. alsoavaliable with gearing.motor actuators, pneumatic or hydraulic actuators for more difficult services. | B)Live Load Packing In services requiring frequent cycling or with high pressure/temperature variations,live loading extends the service life between maintenance periods by requiring less stments. Belleville springs are employed to provide constant packing gland stress. | C)OS&Y Outside screw and yoke.Cast steel gate valve yoke integral with bonnet for 150Lb-8″ 600Lb-6″, 900Lb-4″&small. | ||

| D)BB Bolted bonnet, welding bonnet and pressure seal bonnet in services requiring frequent cycling or with high pressure/temperature variations. | E)End Connections A choice of flanged, RTJ flanged or buttwelding end for piping flexibility. | F)Yoke Sleeve Extra long thread engagement between yoke sleeve and stem provide long thread life.valves of sizes larger than 150Lb-12″, 300Lb-10″,600Lb-6″, 900Lb/1500Lb/2500Lb-4″ are regularly provided with roll bearing yokes. | ||

| G)Lantern Ring And Double Packing Set Lantern ring leak-off fitting connection and double packing stack is optionally avaliable for critical services | H)Body-to-Bonnet Joint A flat face gasket joint is used in the 150lb valves. A male and female joint is used in 300lb to 600lb valves.ring joint is used in the body to bonnet connections in 900lb & higher rated valves. | I)Stem All wedge gate valves are provided with upset forged T-head stems. By forging the T-head ,the stem at the stem-wedge connection is stregthened,this design also allows the wedge possibility of a bent stem jamming the wedge. | ||

| J)Wedge Integral guide rib faces assure self-centering of wedge.flexible wedge gate valve has a onepiece, twin-disc wedge,which is designed so that each half flexes independently.avaliable in solid, flex split and his designs. |

Wedge Gate Valve (Bolted Bonnet type)

| Size | NPS 1/2″~56″ |

|---|---|

| Pressure Rating | Class 150~2500 |

| Material | WCB,LCB,WC6,WC9,C12,C5,CF8,CF8M,CF3 ,CF3M |

| Temperature | -29~540℃ |

| Design & Manufacturing Standard | API 600,BS 1414,ASME B16.34 |

| Face to Face | ASME B16.10,BSEN 558 |

| End Connection | ASME B16.5,ASME B16.47,BSEN 1092 |

| Test and Inspection | ISO 5208,API 600,BS 6755 |

| Structure Type | OS & Y,Bolted bonnet,Single Wedge |

| Operation Method | Manual,Electric Actuator,Pneumatic Actuator |

Design

RAYS cast steel gate valves are designed and manufactured to provide maximum service life and dependability. All gate valves are full ported and meet the design requirements of American Petroleum Institute standard API600&API 6D,British standard BS1414& BS EN 1984 and generally, conform to American Society of Mechanical Engineers standard ASME B16.34. Valves are available in a complete range of body/bonnet materials and trims.

Ranges of Materials

Standard body/bonnet materials include nine grades of carbon, low alloy and stainless steels. For special applications they can be supplied in other grades of alloy and stainless steel. There’s a full range of trim materials to match any service .optional packing and gasket materials are available for a full range of service conditions.

Available Modifications For RAYS Steel Valves

| Trim Changes End Connection Modifications Packing and Gasket Change Operator Mounting Handwheel Extensions | Pressure Equalizing By-Pass Customer Specified Coatings Weld End Bore Changes Oxygen & Chlorine Clearing & Packaging |

Applicable Standards:

●STEEL GATE VALVES API 600/API6D

●STEEL GATE VALVES ISO 10434/ISO 14313

●STEEL VALVES,ASME B16.34

●FACE TO FACE ,ASME B16.10

●END FLANGES ,ASME B16.5

●BUTTWELDING ENDS,ASME B16.25

●INSPECTION AND TEST API 598/API 6D

Design descriptions:

●FULL PORT DESIGN

●OS&Y OUTSIDE SRCEW AND YOKE

●BB.BOLTED BONNET

●FLEXIBLE WEDGE,FULLY GUIDED

●CHOICE OF SOLID OR SPLIT WEDGE

●RENEWABLE SEAT RINGS

●FORGED T-HEAD STEM

●RISING STEM AND NON-RISING HANDWHEEL

●FLANGED OR BUTTWELDING ENDS

●AVAILABLE WITH BG OPERATOR

Design

RAYS steel ball valves are designed manufactured to provide maximum service life and dependability. All ball valves are full ported and meet the design requirements of American Petroleum Institute standard API 608&API 6D British standard BS 5351 and generally conform to American society of Mechanical Engineers standard ASME B16.34 valves are available in a complete range of body/bonnet materials and trims.

Range of Materials

Standard body/bonnet materials include nine grades of carbon, low alloy and stainless steel, for special applications they can be supplied in other grades of ally and stainless steel, there’s a full range of trim materials to match any service optional packing and gasket materials are available for a full range of service conditions.

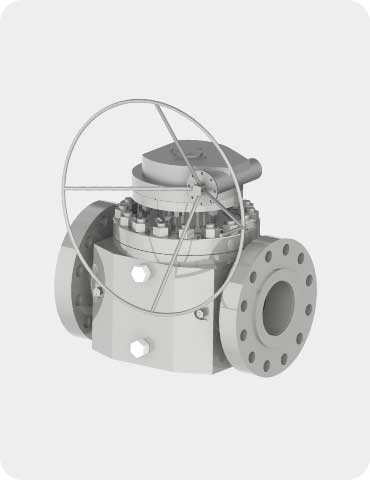

Pressure Seal Gate Valve

| Size | NPS 2″~24″ |

|---|---|

| Pressure Rating | Class 600~2500 |

| Material | WCB,WCC,WC6,WC9,C5,C12,LCB,LCC,CF8, CF8M,CF3,CF3M,CN7M,CF8C |

| Design & Manufacturing Standard | API 600,BS 1414 |

| Face to Face | ASME B 16.10,EN558 |

| Flanged Dimension | ASME B16.5 |

| Butt Weld Dimension | ASME B16.25 |

| Pressure Temperature | ASME B16.34 |

| Test and Inspection | API 598 |

| Operation Methed | Manual,Beree,Electric Actuator, Pneumatic Actuator,Hydraulic Actuator |

Applicable Standards:

STEEL GATE VALVES,API600/API 6D

●STEEL GATE VALVES, ISO 10434/ISO 14313

●STEEL VALVES,ASME B16.34

●FACE TO FACE, ASME B16.10

●END FLANGES ASME B16.5

●BUTTWELDING ENDS,ASME B16.25

●INSPECTION AND TEST ,API 598/API 6D

Design descriptions:

●PSB,PRESSURE SEAL BONNET

●FLEXIBLE WEDGE,FULLY GUIDED

●CHOICE OF SOLID OR SPLIT WEDGE

●RENEWABLE SEAT RINGS

●FORGED T-HEAD STEM

●RISING STEM AND NON-RISING HANDWHEEL

●FLANGED OR BUTTWELDING ENDS

●AVAILABLE WITH BG OPERATOR

| Principle of operation The Through Conduit Double Expanding Gate Valve comprises of a two piece wedged shape assembly consisting of a Gate and a Segment. The Gate is attached and driven by thestem and a centralizer helps in retaining the Gate-Segment assembly until sealing through expansion is required.Positive sealing is achieved in both high and low pressure conditions by expanding the Gate and the Segment out towards the seats while in a closed position. | |

| Gate in fully open position In a fully open position, the Segment is incapable offur ther upward movement and the Gate slides upwardsalong the wedge angle of the Segment, expanding boththe Gate and the Segment. The centralizer mechanism allows the Gate-Segmentassembly to expand against the seats and protect theseat faces from the line flow. | |

| Gate in running position In the running position, the centralizer holds theassembly together, preventing relative movementbetween theGate and Segment and holding themin a neutral position until sealing expansion is required. | |

| Gate in fully closed position With the Segment incapable of fur ther downward movement,simultaneous upstream and downstream sealing is achieved whenthe centralizer mechanism allows the Gate-Segment to expand,sealing against both seats. |

Design features

•Positive Sealing (Capability of improving seal tightness by increasing the stem thrust)

•Through Conduit – Negligible Pressure Drop

•Double Block and Bleed per formances

•Double seal (both up and downstream seats contribute to guarantee tight seal)

•Bi-Directional (with preferred flow direction)

•Full In-Line maintainability

•Suitable for all types of fluids

•Superior life of seat sealing sur face(metal/non-sliding seats)

•Par ticularly indicated for Pig Traps isolation

•Extremely wide range of operatingpressure and temperatures

•Extremely robust constructionIntrinsically Fire Safe construction

MAIN FEATURES

Fully piggable

RAYS Through Conduit Expanding Gate aredesigned to be Fully Piggable. Pigs and scrapers canbe run through the valve without any damage to theinternal structure of the valve.

Easy maintenace

RAYS Through Conduit Expanding Gate valvedesign minimizes and eases the maintenance allowingfor the ser vice operations to be done without theremoval of the valve from the line.

Through Conduit Double Expanding Gate Valve

RAYS Through Conduit Double Expanding Gate Valves are manufactured with a full bore port and with 2-piece (gate + segment) obturator designed for a positive, bubble tight shut off upstream and downstream under both low and high differential pressure. Double block and bleed capability and high robustness are standard feature of this seat design.

The smooth, continuous bore minimizes turbulence within the valve and when in the open position it produces a pressure drop equivalent to a portion of pipe of same length and diameter. The seat faces are outside the flow stream and therefore protected from the erosive action of the flow.

Pigs and scrapers can be run through the valve without damage.

PRODUCTION RANGE

RAYS Through Conduit (T.C.)

Slab Gate Valves are available in sizes and pressure ratings as follows:

•Class 150# from 2″ through 64″

•Class 300# from 2″ through 64″

•Class 600# from 2″ through 64″

•Class 900# from 2″ through 48″

•Class 1500# from 2″ through 42″

•Class 2500# from 2″ through 24″

APPLICABLE STANDARDS

Slab Gate valves comply with API 6D / API 6D SS and all relevant international codes:

•ASME B16.34

•ASME B16.25

•ASME B16.47

•Nace MR01.75

•ASME VIII Div.1

VALVE MATERIALS

RAYS Through Conduit Double Expanding Gate valves are manufacturedusing a wide range of materials, from carbon steel to alloys, in order to complywith all the possible ser vices (Hydrocarbons, Mildly to Highly Corrosive, NACE,etcetera) and applications.ns, Mildly to Highly Corrosive, NACE, etcetera) andapplications.

MAIN APPLICATIONS

•Offshore/Onshore applications

•Double block and bleed applications

•Sub-sea applications

•Scrapers/Pig Traps/Pig Launchers and Receivers

•Oil and gas production/transpor tation isolation

•Upstream gas compressor isolation

•Critical and Primar y isolation

MAIN FEATURES

Seats

Seats are Tungsten Carbide HVOF (High Velocity Oxy Fuel) coated with Metal to Metal contact between seats and gate. Seat faces protected from emersion The seat faces are outside the flow stream and protected from the erosive action of the flow Stem/stem seal The stem is designed with a threaded T bar allowing relative motions of the gate under line pressure. The stem seal uses graphite seals to insure sealing integrity. Upon request a Chevron packing is available. The stem seal is provided with a lantern ring, and may be provided with secondar y injection fitting and stempacking release valve (optional features).

Fire-safe design

RAYS Through Conduit Expanding Gate valve isavailable in the API 6FA fire-tested design. Fire-testshave been witnessed and cer tified by independentauthorities. RAYS Fire tested gate valves offer thehighest resistance against fire. The body seal is aspiral wound gasket or Ring Joint / BX depending onthe valve ser vice and rating, and the stem seal is adie/formed /braided graphite packing.Fire-tests cer tification is available and can be providedupon request.

Double block & bleed

Double block and bleed capability is a standard featureof RAYS Through Conduit Expanding Gate Valves.With the valve fully closed and pressure on both sides,it is possible to bleed the pressure from the bodycavity to check seat seal integrity.

Double isolation

This feature is obtained since the valve sealing isgranted not only by the line pressure but also by theexternal force used to close the valve ( i.e. positivesealing)

VALVE MATERIALS

| General non corrosive | Body | Bonnet | Trim | Seat Insert |

|---|---|---|---|---|

| Moderate corrosive | A216 WCB | A105 | A105 + ENP | Nylon/RPTFE |

| Low temperature | A216WCB | A105 | F6A | Nylon/RPTFE |

| Service | A352 LCC | LF2 | LF2 + ENP | Nylon/RPTFE |

TYPICAL ADVANTAGES

•Negligible Pressure Drop

•Self – Relieving

•Double Block and Bleed performances

•Equalized Bore (as required/operated)

•Possibility of reverse acting and

equalized bore for fail closed operation

•Double seal upstream by piston effect, down-stream with floating obturator

•Superior Seal Per formances (Bubble Tight)

•Suitable for all types of fluids (including abrasive fluids)

•Suitable for ESDV/BDV applications and Pig Traps

•Extremely flexible actuation with or without stem ejection assistance

•Robust Construction

•Full In-Line maintainability

•Fire Safe construction

Through Conduit Slab Gate Valve

RAYS Through Conduit (T.C.) Slab Gate Valves are manufactured with a full bore port, rising stem OS&Y and with floating seats and gate, pressure energized, for a bubble tight shut off upstream and downstream under both low and high differential pressure. Double block and bleed capability and automatic relief of excess body pressure are a standard feature of this seat design. The smooth, continuous bore minimizes turbulence within the valve and when in the open position it produces a pressure drop equivalent to a portion of pipe of the same length and diameter. The seat faces are outside the flow stream and therefore protected from the erosive action of the flow. Pigs and scrapers can be run through the valve without damage.

PRODUCTION RANGE FEATURES

Slab Gate Valves are available in sizes and pressure ratings as follows:

•Class 150# from 2″ through 64″

•Class 300# from 2″ through 64″

•Class 600# from 2″ through 64″

•Class 900# from 2″ through 48″

•Class 1500# from 2″ through 42″

•Class 2500# from 2″ through 24″

APPLICABLE STANDARDS

Slab Gate valves comply with API 6D / API 6D SS and all relevant international codes:

•ASME B16.34

•ASME B16.25

•ASME B16.47

•Nace MR01.75

•ASME VIII Div. 1

Additional features (Available on request)

• Metal seated/Tungsten Carbide coating for abrasive fluids

• Stem extension for buried ser vice/high temperature ser vice

• Inconel 625 cladding of the sealing sur faces for corrosive ser vice

• CRA alloys for ver y corrosive media (Duplex,UNS S31254,UNS S34565)

• Seat Sealant Injection system for Emergency Sealing

• Transition Pipe Pups welded to the valve ends

• Position indicator

• Actuation (Electric, Pneumatic and Hydraulic actuators)

Self relieving features

The single piston design with the possibility of both seats and gate to float, permits the automatic release of any overpressure in the body cavity.

Consequently, the seat rings are “self-relieving”.

Applicable Standards:

●STEEL GATE VALVES, API 602

●STEEL VALVES,ASME B16.34

●FACE TO FACE, MANUFACTURER STANDARD

●FACE TO FACE, FLANGED ,ASME B16.10

●END FLANGES,ASME B16.5

●BUTTWELDING ENDS,ASME B16.25

●SOCKET-WELDING ENDS,ASME B16.11

●SCREWED ENDS,ASME B1.20.1

●INSPECTION AND TEST, API 598

Design descriptions:

●OUTSIDE SCREW AND YOKE (OS&Y)

●BOLTED BONNET

●CHOICE OF WB, WELDED BONNET

●SINGLE WEDGE,FULLY GUIDED

●RENEWABLE SEAT RINGS

●YOKE INTEGRAL WITH BONNET

●RISING STEM AND NON-RISING HANDWHEEL

●SW,SOCKET-WELDING ENDS

●SC,SCREWED ENDS

●BW,BUTTWELDING ENDS

●FLANGED ENDS

Forged Steel Gate Valve

| Size | NPS 1/2″~2″ |

|---|---|

| Pressure Rating | Class 150~1500 |

| Material | A105,LF2,F5,F9,F11,F22,F304,F304L,F311,F51 |

| Design & Manufacturing Standard | API 602,ASME B16.34,BS 5352 |

| Face to Face | ASME B16.10,EN 558(threaded and sw as per manufacturer’s std) |

| Flanged Dimension | ASME B16.5 |

| Butt Weld Dimension | ASME B16.25 |

| Thread Connection Dimensions | ASME B 1.20.1 |

| Test and Inspection | API 598 |

| Type | Gate |