ONZE KOGELKRANEN

LEVERERANCIER KOGELKRANEN

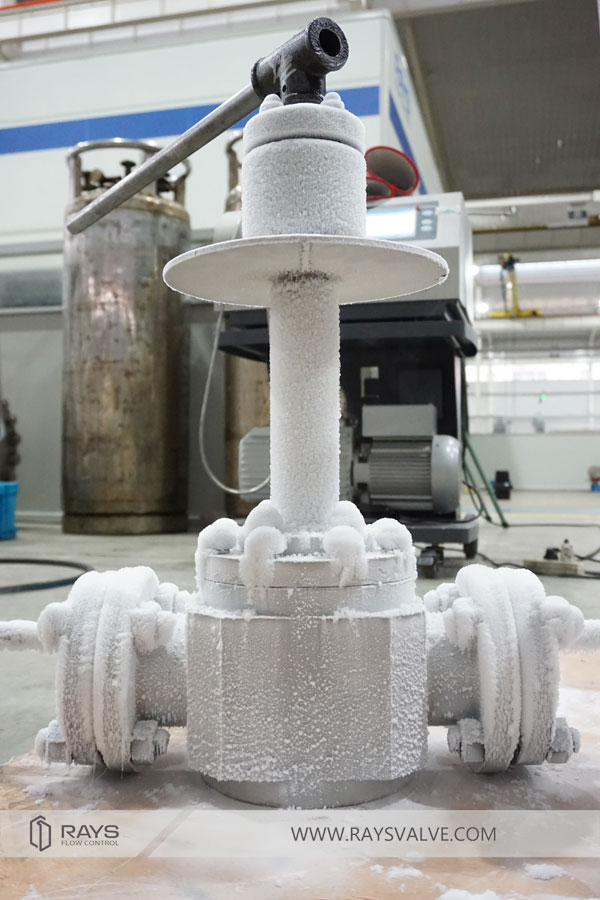

Cryogenic Ball Valve

Side Entry Trunnion Mounted Ball Valves

Double Block and Bleed Ball Valves (Soft and Metal Seated)

Top Entry Ball Valve

Rising Stem Ball Valve

Full Welding Ball Valve

Floating Ball Valve

BELANGRIJKE INFORMATIE

Al onze beschrijvingen en benamingen van specifieke kleppen en afsluiters zijn in het Engels

Cryogenic Ball Valve

Applications

- Liquefied natural gas (LNG)

- Liquefied petroleum gas (LPG)

- Liquefied oxygen

- Liquefied hydrogen.

- Air separation industry

Design Features & Benefits

- Extended bonnet design to ensure reliability of the stem packing & sealing.

- Drainage board design to prevent condensation water.

- Anti-Statistic & Fire-safe Design.

- Cavity automatic self pressure relief, suitable and safe for explosive medium.

- Live-load API 622 certified graphite and lip-seal sealing to ensure API 624 fugitive emission compliance.

- Suitable for working temperature as low as -196℃ .

- Multiple Seat Design option, suitable for various working medium and condition.

- Top Entry or Side Entry optional design.

Design

RAYS steel ball valves are designed manufactured to provide maximum service life and dependability. All ball valves are full ported and meet the design requirements of American Petroleum Institute standard API 608&API 6D British standard BS 5351 and generally conform to American society of Mechanical Engineers standard ASME B16.34 valves are available in a complete range of body/bonnet materials and trims.

Range of Materials

Standard body/bonnet materials include nine grades of carbon, low alloy and stainless steel, for special applications they can be supplied in other grades of ally and stainless steel, there’s a full range of trim materials to match any service optional packing and gasket materials are available for a full range of service conditions.

Side Entry Trunnion Mounted Ball Valves

| Size | NPS 2″ – NPS 56″ |

|---|---|

| Pressure Rating | Class 150LB – Class2500LB |

| Material | WCB, LCB, CF8, CF8M, CF3, CF3M, A105, LF2, F304, F316, F304L, F316L |

| Design & Manufacturing Standard | API 608, API 6D, BS 5351, ASME B16.34 |

| Fact to Face | ASME B16.5, API 6D |

| End Connection | ASME B16.5, ASME B16.47, ASME B16.25 |

| Test and Inspection | ISO 5208, API 6D |

| Operation Method | Manual, Worm Gear, Electric Actuator, Pneumatic Actuator |

Applicable Standards

● STEEL BALL VALVES API 608/API 6D

● STEEL BALL VALVES ISO 14313

● FIRE SAFE,API 607

● ANTI STATICS,API 608

● STEEL VALVES,ASME B16.34

● FACE TO FACE ASME B16.10

● END FLANGES,ASME B16.5

● BUTTWELDING ENDS ASME B16.25

● INSPECTION AND TEST, API 598/ API 6D

Design descriptions

● FULL PORT DESIGN

● BB.BOLTED BONNET.SPLIT BODY

● THREE PIECES BODY FOR 12″ & ABOVE

● TRUNNION MOUNTED BALL TYPE

● BLOW-OUT PROOF STEM

● FIRE SAFE CONSTRUCTION

● ANTI STATICS DEVICE

● STOPPER DEVICE

● ISO 5211 MOUNTING PAD

● FLANGED OR BUTTWELDING ENDS

● AVAILABLE WITH WG OPERATOR

CHARACTERISTICS

•Anti blow out/low emission stems

•Fire safe & anti-static design

•Independent ball and stem

•Self aligning trims

•Self relieving/ Double piston effect

floating seats

•Soft or metal seated

Design is available in side entry, (bolted, welded body) and for onshore, offshore (top side) or sub-sea configurations.

Bleed/Vent system can be provided with Globe, Gate or Ball valves as per customers requirement.

Double Block and Bleed Ball Valves (Soft and Metal Seated)

The “Double Block and Bleed Isolation Philosophy” requires two in-line isolation valves and a bleed valve, used to drain or vent trapped fluid between the two closure elements in order to safely isolate safely the downstream pipe. This feature can be achieved with one single valves c/w a bleed port between the obturators.

MAIN APPLICATIONS

•Offshore oil & gas production

•Gas & oil terminals

•Chemical & Petrochemical

•Refining

•Fiscal Metering Skid Manufacturing

•LNG gas carrier

•Process/ Power industr y contractors

ADVANTAGES

•Space and weight saving

•Cost saving (product & installation)

•Minimized leak paths

•Increased line structural integrity

•ESDV+MOV or ESDV+XV configurations

•Increasesd reliability of the system

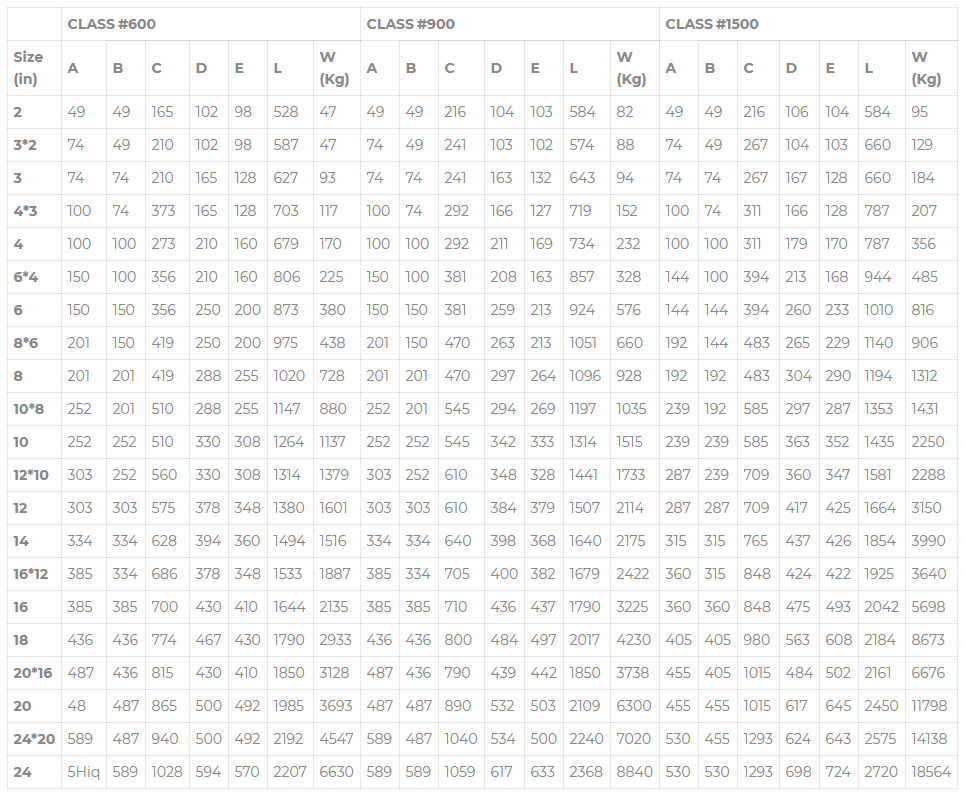

•All dimensions except where other wise specified are in mm.

•Weight figures are relevant to flanged end valves.

•Note: For dimensions and weights in larger sizes consult the factory.

•Dimensions C, D, E, and weights are subject to changewithout notice.

•Face-to-face dimensions not listed in industry standards are subject to change without notice.

Materials of parts

| Body Lid Ball Seat Stem Seat ring O-ring Bolt Support cover Spring Bearing Gasket | WCB/LCB/CF8M/CF8/CF3M/CF3/WC6/WC9/CD3MN WCB/LCB/CF8M/CF8/CF3M/CF3/WC6/WC9/CD3MN A105+ENP/LF2+ENP/F304/F316/F304L/F316L/F51 A105+ENP/LF2+ENP/F304/F316/F304L/F316L/F51 A105+ENP/LF2+ENP/F304/F316/F304L/F316L/F51 PTFE/MYLON/PEEK/TEFLON VITON/NBR B7M/B8M/L7M/B16M A105+ENP/LF2+ENP/F304/F316/F304L/F316L/F51 17-4PH/17-7PH/Inconel 304+PTFE/316+PTFE Flexible graphite+PTFE |

Top Entry Ball Valve

| Size | NPS 2″~24 |

|---|---|

| Pressure Rating | Class 150~2500 |

| Material | WCB,LCB,CF8,CF8M,CF3,CF3M,A105,LF2,F304,F316,F304L,F316L |

| Design & Manufacturing Standard | API 608,API 6D,BS 5351,ASME B 16.34 |

| Face to Face | ASME B 16.10,API 6D |

| End Connection | ASME B16.5,ASME B 16.47,ASME B 16.25 |

| Test and Inspection | ISO5208,API 6D |

| Operation Method | Manual,Worm Gear,Electric Actuator,Pneumatic Actuator |

Applicable Standards:

DESIGN & MANUFACTURE CONFORM WITH: API 6D/ISO 14313,ASME B16.34

CONNECTION DIMENSION CONFORMS WTIH:ASME B16.5,DN EN 1092

FIRE RESISTANCE DESIGN CONFORMS WITH:API 607/ISO 10497

INSPECTION & TEST CONFORMS WITH:API 6D,ISO 5208,API 598

MATERIAL CONFORMS WITH:ISO 15156

Features and Application:

Top Entry Combination Ball Valve

This product is a new type top entry combination ball valve,the seat can be installed and move around the body. Through the thread, the outer margin of the

seat connected to the retainer ring. There is spring on the support cover, which installed on the valve body, and the retainer ring can compress spring.

The fabrication holes are on the outer margin of the seat and the retainer ring. This new type product adopts total body design, the compensation can

be automatically, the possibility of leakage is small, safety in use, vibrate resistance, and double seal. The ball is installed from the top part, so can finsish

the maintenance without removing the pipe, it is very convenient.

When tilting away from the seat, the medium fluid along the sealing surface 360 ° and some foreign sundry is rinsed clean, with self-cleaning function, the RSBV on the long-distance can be used pipeline pigging. RSBV is venting gas emission, transmission, fluid pipeline, shut off, the bypass, product partition, pipeline emergency shut off, high switching frequency, the ideal valve of zero leakage requirements in higher and harsher conditions.

DESIGN ADVANTAGES

RSBVs are ideal applications to zero leakage and frequent operation are demanded. They are used universally in gas processing plants using molecular sieve systems in switching service

STEM SEALING

No Rubbing Between Sealing Surfaces

RAYS RSBV with its unique structure of the stem and valve seat in the valve open-close process without friction, which could extend valve life sealing is more reliable.

Injectable Packing: Stem packing material is injected through the packing fitting in-service maintenance, giving complete control of fugitive emissions.

Single-seat Design: The single, stationary seat in the RAYS RSBV valve seals in both directions and avoids the problems of trapped pressure between seals.

Long Life: RAYS RSBV could replace many troublesome valves such as ball valves, gate valves, globe valves and plug valves. The RAYS RSBV design has performance advantages that reduce plant outage and reduce the cost dramatically of ownership.

Optimum Flow: Full port or reduced port openings give high CV figures. System pumping efficiency is enhanced and erosion problems are reduced.

Ball &Seat Self-cleaning Function: Design of opening of the media along the 360 direction of the ball and the valve seat surface has a self-cleaning function.

Low-torque Operation: RSBV valves turn easily because seal rubbing is eliminated.

Various Seat Structure: Either soft seated or metal seated with various material options, can be applied to low temperature, normal temperature, high temperature and also many other working condition.

Top-entry Design: Could be easily operated directly in-line inspection and repair, after system depressurizing, simplifies maintenance.

Dual Stem Guides: Hardened stem slots and tough guide pins control the stem action of lift-and-turn.

Rising Stem Ball Valve

| Sizes | 1” through 24” |

|---|---|

| Pressure Ratings | ANSI Classes 150 through 2500, DIN PN 10 through PN 320 |

| End Connections | Flanged RF/RJ, Butt weld, Socket weld, Hub end, Screwed |

| Face to Face | To B16.10, Manufacturer Std. or at special request |

| Trim Area | Full bore or Reduced bore to API 6D dimensions or at special request |

| Packing Options | Graphite or PTFE or combination composition at request |

| Flow Direction | Preferred flow toward seat or Bi Directional at request |

| Leakage Rates | To API 598 or BS 6755 or ANSI FCI-70-2 Class V or VI |

| Flow Coefficients | Cv Value as per the enclosed tables pages 6 through 11 |

| Temperature Range | From minus 196 ˚C to 600 ˚C |

General Introduction

RAYS Rising Stem Ball Valve abbreviated as RAYS RSBV with its unique design especially such as the opening process no friction character and turn-off zero leakage. Performance is particularly suitable for special requirements for various extremely harsh working conditions, all-metal structure design, fire proof design, can adapt to low temperatures ranges between -204°C or (-400°F), and high temperature could be up to 815°C or (1500°F) operating temperature, also can adapt to the impurity medium(including sand, short fibers) condition requirements. Particularly worth pointing out is that we are fully according to the American association of corrosion factory NACE standard requirements in design, material selection meets the requirements in sulfide environment of sulfide stress cracking resistance.

APPLICATIONS

- Petroleum – Craft cutting and control of offshore platforms, oil slurry system, all cut and control such as water torch, shut off valve and adjusting valve of storage tank, and cut and control of oil pipeline end.

- Natural gas – Craft cutting and control of offshore platforms, all cut and control applications in processing and purification plant, shut off valve and control valve of natural gas storage tank, and cut off applications in the end of transmission pipelines.

- Chemical plant – Application process. Apply to the applications of all cutting off and control, and the cut and control applications of steam system.

- Pulp and paper reduction process application, ethanol reduction process application, and steam application.

- Power station – Application of low pressure steam. Cut and control, regional heating boiler and distribution pipes, and trap valve.

- Steel mill – Furnace gas cut-off valve.

| ANSI Pressure Class | Size Range |

|---|---|

| 150 | 1” – 24” |

| 300 | 1” – 24” |

| 600 | 1” – 24” |

| 900 | 1” – 20” |

| 1500 | 1” – 16” |

| 2500 | 1” – 8” |

Materials of parts

| Body Ball Seat Stem Sealing ring O-ring Screw Support cover Die holder Spring Bearing Gaske | A105/LF2/F304/F316/F304L/F316L/F11/F22/F51 A105+ENP/LF2+ENP/F304/F316/F304L/F316L/F51 A105+ENP/LF2+ENP/F304/F316/F304L/F316L/F51 A105+ENP/LF2+ENP/F304/F316/F304L/F316L/F51 PTFE/NYLON/PEEK/TEFLON VITON/NBR B7M/B8M/L7M/B16M A105+ENP/LF2+ENP/F304/F316/F304L/F316L/F51 A105+ENP/LF2+ENP/F304/F316/F304L/F316L/F51 17-4PH/17-7PH/Inconel 304+PTFE/316+PTFE Flexible graphite+304/PTFE |

Full Welding Ball Valve

| Size | NPS 2″~48″ |

|---|---|

| Pressure Rating | Class 150~1500 |

| Material | A105,LF2,F304,F316,F304L,F316L |

| Design & Manufacturing Standard | API 608,API 6D,BS 5351,ASME B 16.34 |

| Face to Face | ASME B 16.10,API 6D,DIN 3202 |

| End Connection | ASME B16.5,DIN 2543-2550,ASME B 16.25 |

| Test and Inspection | ISO5208,API 6D,BS 6755 |

| Operation Method | Manual,Worm Gear,Electric Actuator,Pneumatic Actuator |

Applicable Standards

DESIGN & MANUFACTURE CONFORM WITH: API 6D/ ISO 14313,ASME B16.34

CONNECTION DIMENSION CONFORMS WTIH: ASME B16.25,DIN EN 12627

FIRE RESISTANCE DESIGN CONFORMS WITH: API 607/ISO 10497

INSPECTION & TEST CONFORMS WITH: API 6D,ISO 5208,API 598

MATERIAL CONFORMS WITH: ISO 15156

Materials of parts

| 1 2 3 4 5 6 7 8 9 10 11 | Body Left-right body Ball Seat Sealing ring O-ring Stem Seat grease injection valve Spring straight pin Blow-down vavle | 12 13 14 15 16 17 18 19 20 21 22 | Ball lubricating bearing Screw Bonnet gasket Support cover Die holder Packing Terminal pad Spring pin Flat key Stem gasket Static-free spring |

Available Modifications For RAYS Steel Valves

| Trim changes End connection modifications Packing and gasket change Operator mounting Handwheel extensions | Pressure equalizing As or fd Customer specified coatings Weld end bore changes Oxygen&chlorine cleaning & packaging |

| A)Operation Extended lever for easy operation. Also available with gearing, motor actuators, pneumatic or hydraulic actuators for more difficult services | B)Body & Bonnet Split or 3-piece,split body& bonnet for 12″ & small. Disassembles easily for repair or replacement of internal components. | C)BORE Full bore or reduced bore. Full-bore design provides exceptional flow control. | ||

| D)End Connections A choice of flanged RTJ flanged or buttwelding end for piping flexibility. | E)Packing Std packing multiple v-teflon packing, combined with live loading,maintains packing compression under high-cycle and severe service applications. | F)BPS Blow-out proof stem, a pressure-safe stem shoulder design that protects against failure under excess pressure. |

| G)AS Anti statics. A metallic contact is always granted between ball and stem /body to discharge eventual statics build-up during service. | H)FS Fire safe designed to API607 or BS 6755 to grant their operation suitability in case of fire. Secondary metal-to metal seal acts as backup if primary seal is destroyed by fire. Valves ordered for compliance with API 607 will be provided with graphite packingand gaskets. |

Floating Ball Valve

| Size | NPS 1/2″~12″ |

|---|---|

| Pressure Rating | Class 150~1500 |

| Material | WCB,LCB,CF8,CF8M,CF3,CF3M,A105,LF2,F304,F316,F304L F316L |

| Design & Manufacturing Standard | API 608,API 6D,BS 5351,ASME B16.34 |

| Face to Face | ASME B16.10,API 6D,BSEN 558 |

| End Connection | ASME B16.5,BSEN 1092 |

| Test and Inspection | ISO5208,API 6D,BSEN 12266 |

| Operation Method | Manual,Worm Gear,Electric Actuator,Pneumatic Actuator |

Design

RAYS steel ball valves are designed manufactured to provide maximum service life and dependability. All ball valves are full ported and meet the design requirements of American Petroleum Institute Standard API 608&API 6D British standard BS 5351 and generally conform to American Society of Mechanical engineers standard ASME B16.34 valves are available in a complete range of body/bonnet materials and trims.

Ranges of Materials

Standard body/bonnet materials include nine grades of carbon, low alloy and stainless steel, for special applications they can be supplied in other grades of alloy and stainless steel. There’s a full range of trim materials to match any service optional packing and gasket materials are available for a full range of service conditions.

Applicable Standards:

●STEEL BALL VALVES API 608/API 6D

●STEEL BALL VALVES ISO 14313

●FIRE SAFE,API 607

●ANTI STATIC,API 608

●STEEL VALVES,ASME B16.34

●FACE TO FACE ASME B16.10

●END FLANGES,ASME B16.5

●BUTTWELDING ENDS ASME B16.25

●INSPECTION AND TEST, API 598/ API 6D

Design descriptions:

FULL PORT DESIGN

●BG.BOLTED BONNET.SPLIT BODY

●FLOATING BALL TYPE

●BLOW-OUT PROOF STEM

●FIRE DURABLE CONSTRUCTION

●ANTI STATIC DEVICE

●STOPPER DEVICE

●ISO 5211 MOUNTING PAD

●FLANGED OR BUTTWELDING ENDS

●AVAILABLE WITH WG OPERATOR